0102030405

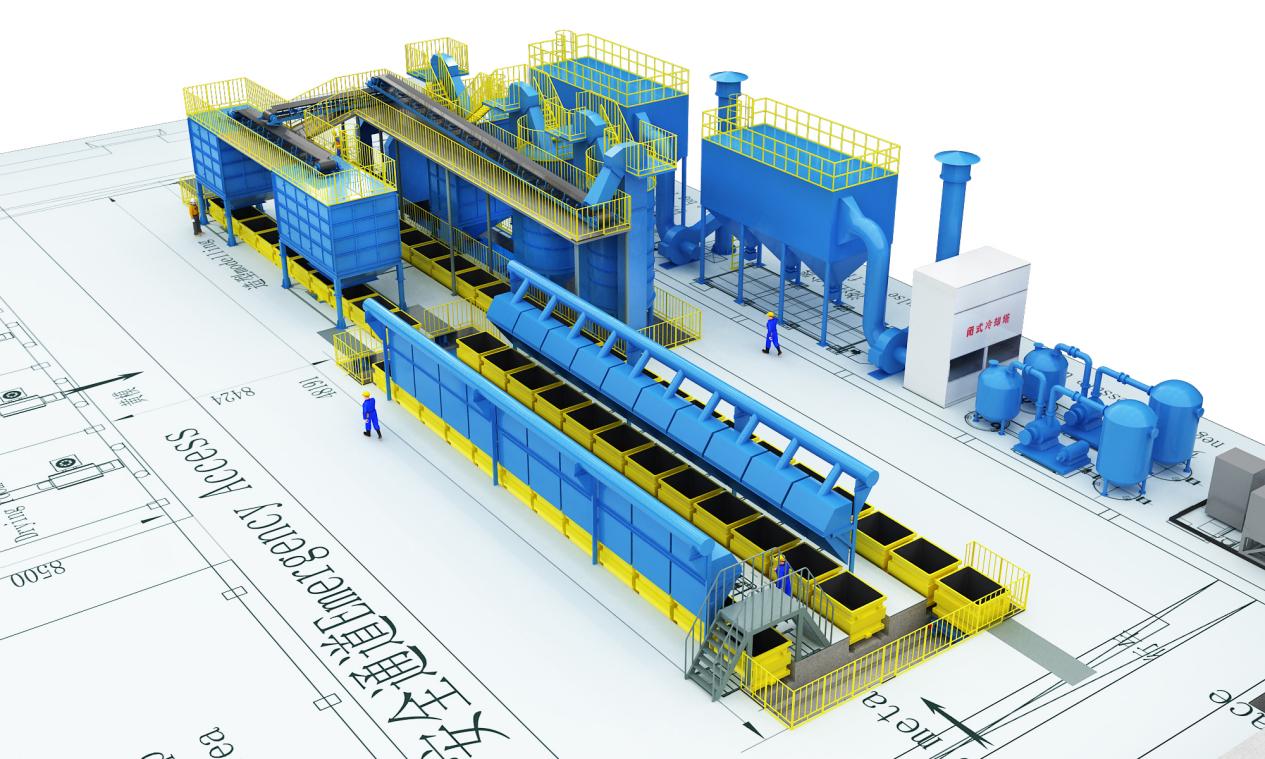

Yunnan Customer's Annual Output of 50,000 Tons of Machine Tool Parts Lost Foam Equipment Production Line

2024-06-29

The demand for high-quality machine tool parts has been on the rise, especially in the manufacturing industry. To meet this demand, Yunnan customer has invested in a state-of-the-art lost foam casting equipment production line. This production line is designed...

view

detail

The installation of Dandong disappearing mold equipment production line has been completed

2024-06-15

The on-site lost foam equipment production line for Dandong customers has been installed, which will significantly improve production efficiency.

Dezhou customer lost molding sand processing line

2024-01-17

Dezhou customer launches a new lost foam equipment production line for motor casings with an annual output of 20,000 tons.

Zibo customer built lost mold casting equipment production line

2024-01-17

Constructing a lost foam casting equipment production line with an annual output of 10,000 tons for Zibo customers to achieve perfect delivery.