Electric Drying Heater For Drying Room

description2

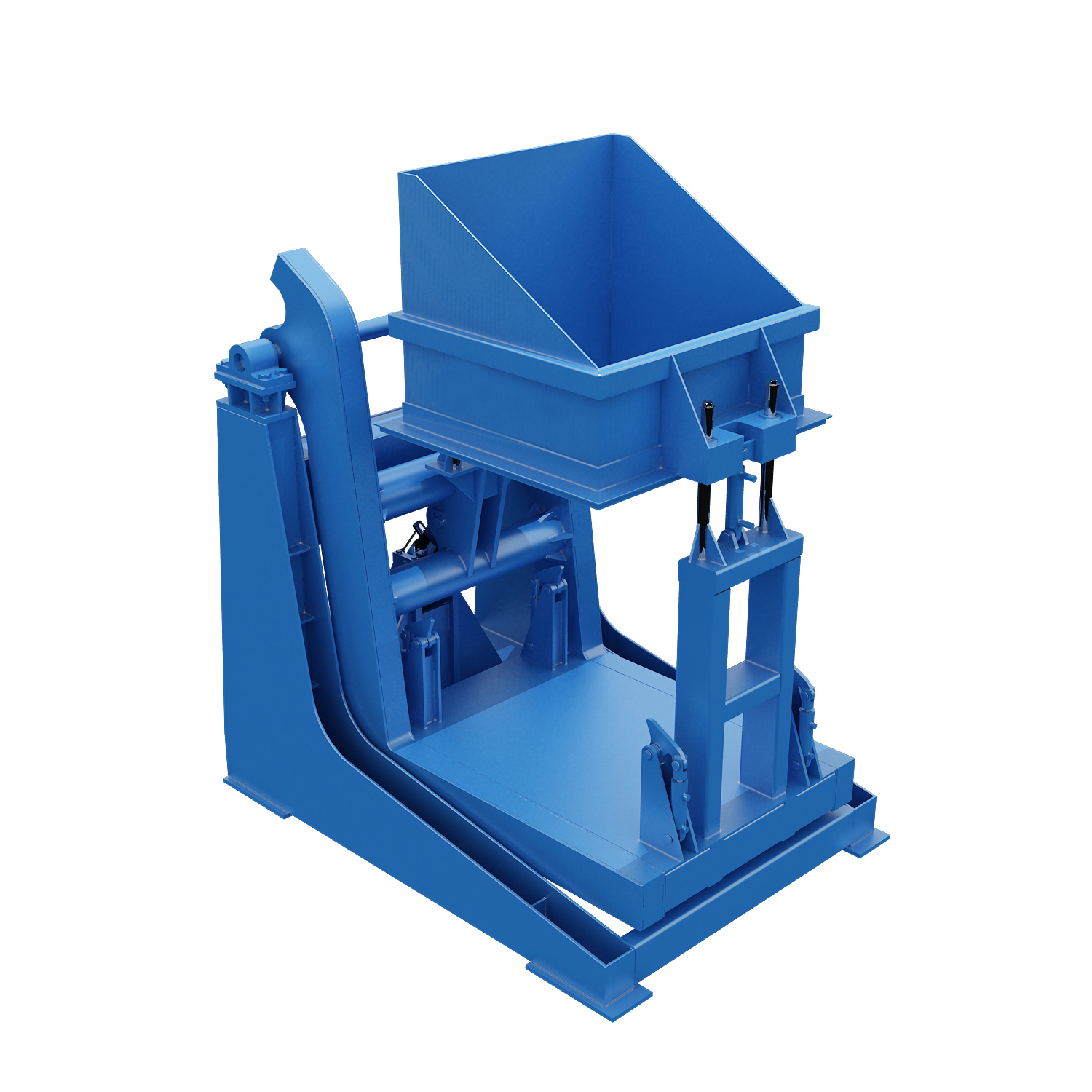

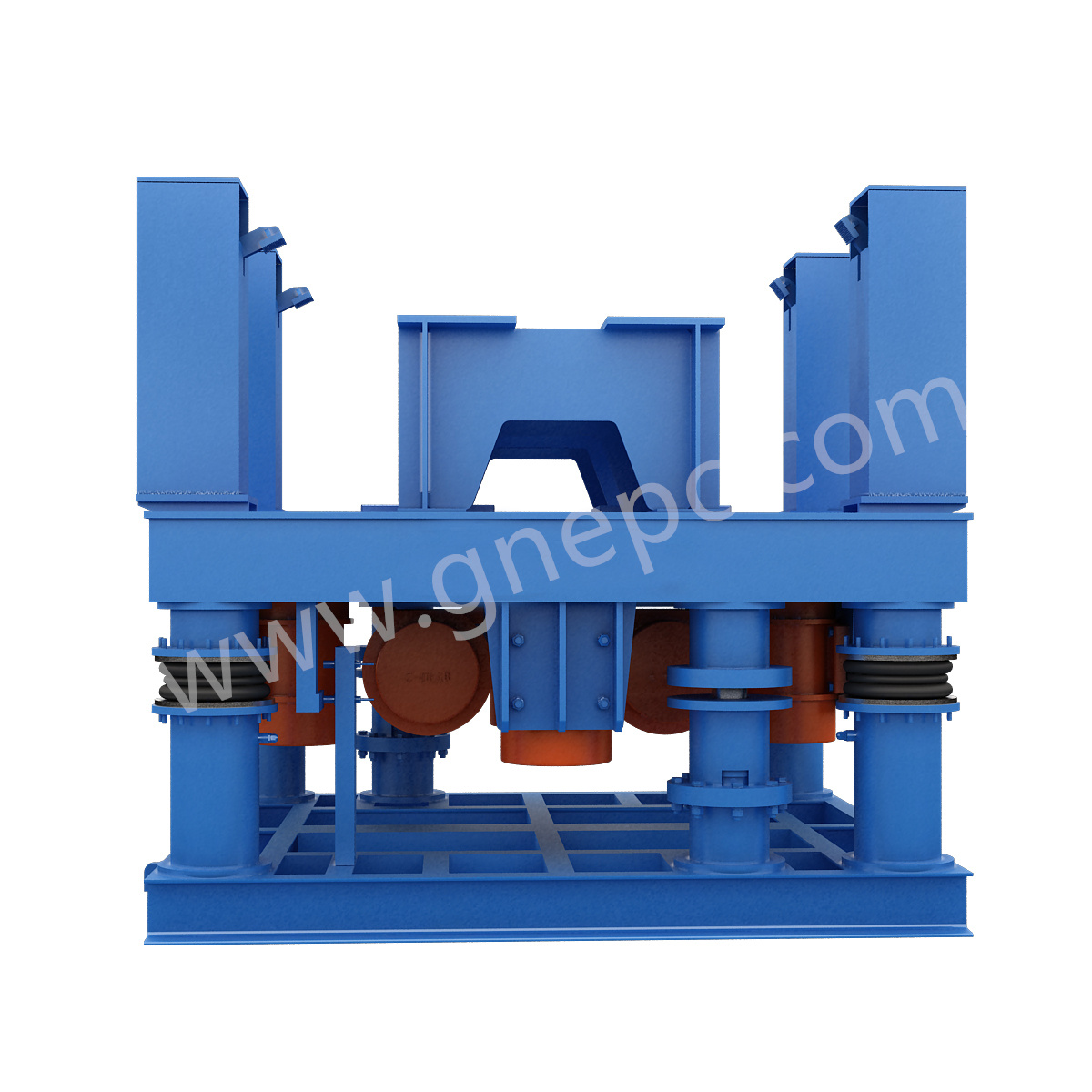

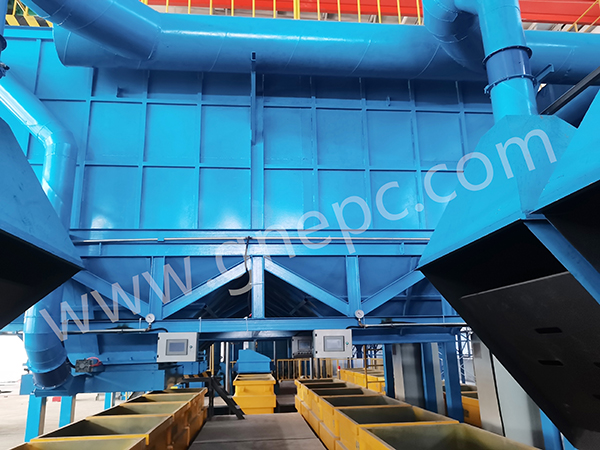

product display

Main technical parameters

specification and model |

overall dimensions |

heating power (KW) |

heating area(㎡) |

heating method |

GNJR-Ⅰ(01) |

900×510×660 |

9 |

20 |

Electric heating |

GNJR-Ⅰ(02) |

870×510×1175 |

15 |

30-50 |

Electric heating |

power requirements: ac power with a rated frequency of 50Hz and a rated voltage of 380V (deviation ± 5%). | ||||

Product overview

- The drying heater mainly consists of a cover plate, a frame, a heating pipe, an axial flow fan, a protective net, etc. Start up preheating and delay air supply (heating the heating pipe before air supply), and after the heating stops, the fan continues to rotate to blow out the remaining temperature.

- The control cabinet includes phase loss protection and overheating protection, which automatically cuts off power when the voltage is unstable.

- The control cabinet includes temperature and humidity control, and the control cabinet is fixed to the outside by external connection.

- Temperature control: When the temperature is reached, turn off the machine, and when the temperature is below, turn on the machine humidity control.

- The temperature and humidity meter controls our self-provided dehumidification axial flow fan model through sensor feedback: ZPW92L35-4E-300 (220V).

Main functions and advantages

This machine adopts an electric heating method, and the heat energy generated by the heating pipe is driven by the axial flow fan air volume to generate circulating hot air, which can achieve large-scale heating in the drying room.

The heating process does not produce any impurities or gases, and can maintain environmental hygiene and cleanliness without pollution.

Versatility is one of the standout features of our electric heater. It can be used as the main heating equipment in a model drying room, where precise temperature control is essential for achieving the desired drying results. Additionally, it can also serve as auxiliary heating equipment in a steam drying room, providing supplemental heat to the existing systems.maintenance, and safe use.