Exhaust Gas Treatment Equipment For Lost Foam Casting

description2

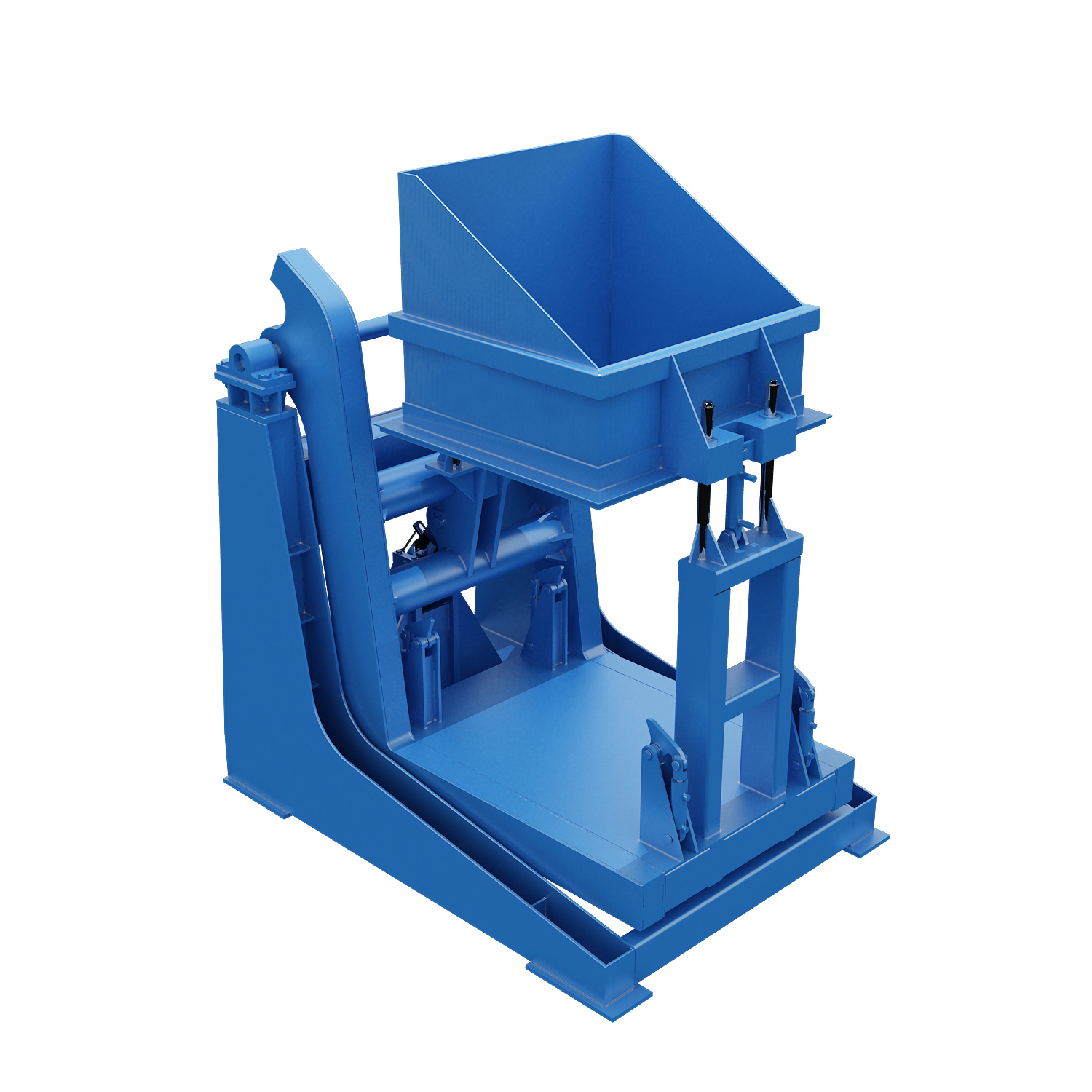

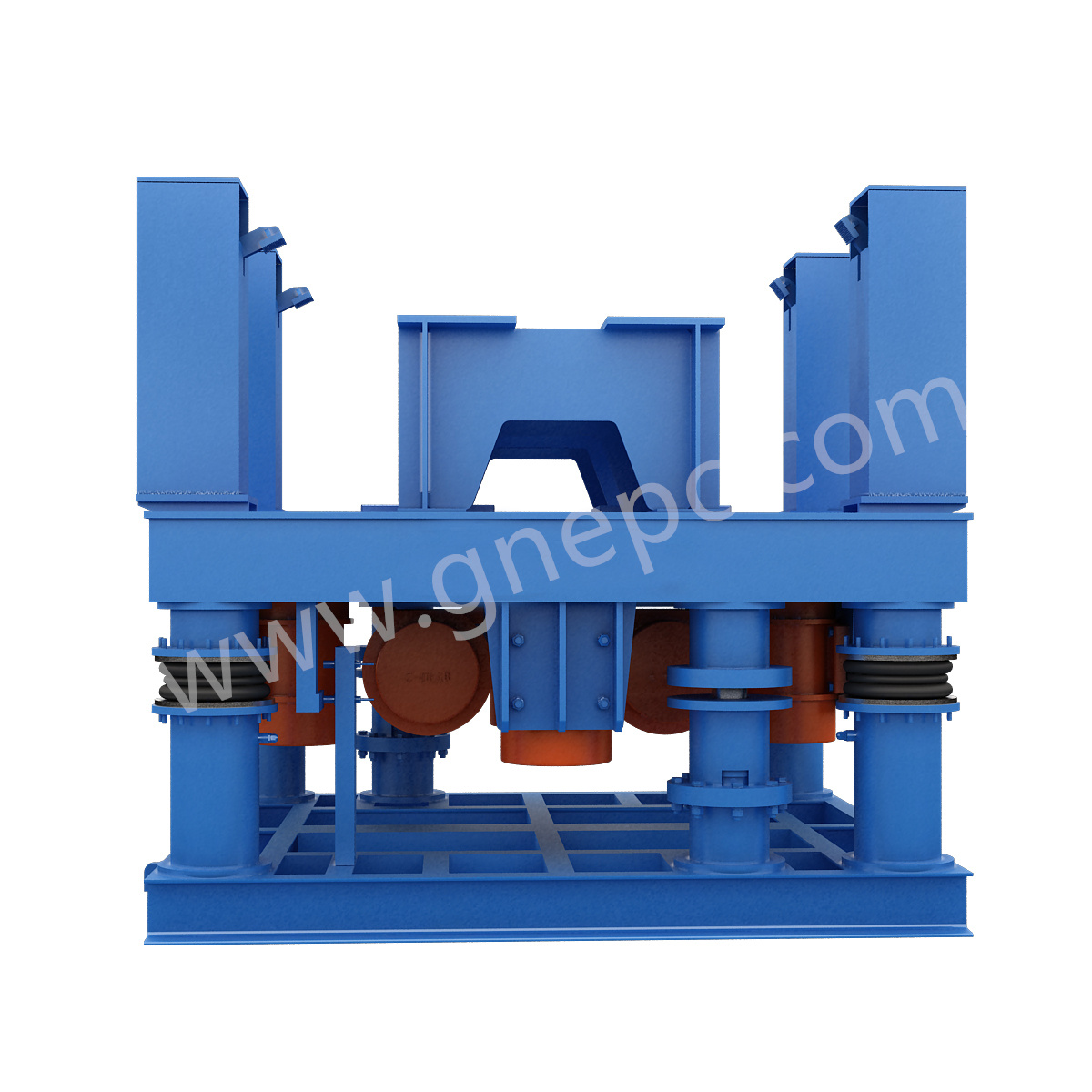

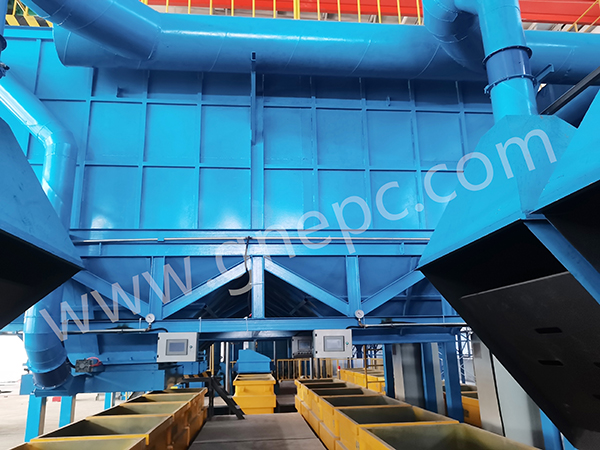

product display

Main technical parameters

- Processing air volume: 10000/20000/30000m ³/ h;

- Combined system of adsorption concentration desorption and catalytic combustion equipment: 1 adsorption bed; Carbon consumption: 1.5 cubic meters;

- Activated carbon adsorption bed: The main material is Q235, made of 1.5 thick steel plate, and the inner plate is 1.2 galvanized plate, containing 5cm silicate rock insulation;

- CO catalytic combustion furnace: The main material of the shell is Q235, with a thickness of 2.0 and 8 inner plates. It is filled with 10CM silicate rock for insulation treatment. The heating tube fins are made of 304 stainless steel, with 30 heating tubes and a total power of 60KW. Plate heat exchanger;

- Main air centrifugal fan with frequency conversion: 4-72-6C-15KW, including 15KW frequency converter;

- Desorption centrifugal fan: 9-19-4C 2.2KW;

- Electric control system: intelligent touch screen PLC automatic control.

Main functions and advantages

Activated carbon adsorption system: The exhaust gas enters the activated carbon adsorber for adsorption, and after passing through the adsorber, it is discharged into clean air that meets the emission standards.

Desorption system: When the adsorber is saturated, it will enter a desorption state and use hot air to desorb the organic solvents in the adsorber, discharging high concentration waste gas into the CO device.

Catalytic combustion system: High concentration organic waste gas is first heated up to the CO starting temperature through a heat exchanger. If the temperature cannot be reached, the electric heating method is turned on to raise the temperature to the starting temperature. After the waste gas enters the catalytic combustion chamber, it starts combustion and purification on the catalyst. The temperature of the emitted flue gas can reach 400-500 ℃. When the concentration of organic waste gas reaches a certain level, it can maintain spontaneous combustion in the catalytic bed without external heating, At this point, the electric heating can be stopped.

The flue gas after combustion is preheated by a heat exchanger and enters the catalytic bed for combustion. The cooled flue gas is then exchanged with fresh air to control the temperature of the desorbed gas at around 120 ℃, and then discharged into the chimney through the exhaust valve. After desorption, proceed to the next cycle.

Equipment characteristics

The catalytic combustion process is used to purify organic waste gas, which can simultaneously remove multiple organic pollutants. It has the advantages of simple process flow, compact equipment, and reliable operation.

The use of electric heating for start-up has the advantages of convenience and low operating costs.

The process has multiple safety protection measures to ensure the safe operation of the system.

There is no wastewater generated during the entire process, and there is no secondary pollution generated during the purification process.

Has high purification efficiency, generally reaching over 97%.

Catalyzer

use |

purification of harmful waste gases such as triphenyls and oxygen-containing organic compounds |

catalyst specifications(mm) |

100×100×50 |

carrier material |

cordierite |

thermal expansion coefficient(10-6/℃) |

1.6-1.8 |

compressive strength(MPa) |

longitudinal ≥ 13; lateral ≥ 5 |

coating specific surface area(m2/g) |

120-150 |

treatment of exhaust gas oxygen content(v/v),% |

≥2.0 |

using airspeed(h-1) |

15000 |

waste gas treatment concentration(ppm) |

≥200 |

The equipment process is a bit complicated

By collecting the exhaust gas with a large fluctuation range into the adsorbent in the adsorber through the adsorber, and then using catalytic combustion equipment to desorb and burn the VOC exhaust gas adsorbed in the adsorber, the concentration of exhaust gas entering the catalytic combustion chamber can be controlled to be stable. Compared with the exhaust gas with a large fluctuation in concentration directly entering the catalytic combustion chamber before, the energy consumption can be reduced by 30-50%.

After concentrating the exhaust gas through the adsorber, the concentration of the exhaust gas entering the catalytic combustion chamber is controllable and the exhaust gas with large concentration fluctuations enters the catalytic combustion chamber for combustion, greatly improving safety.