01

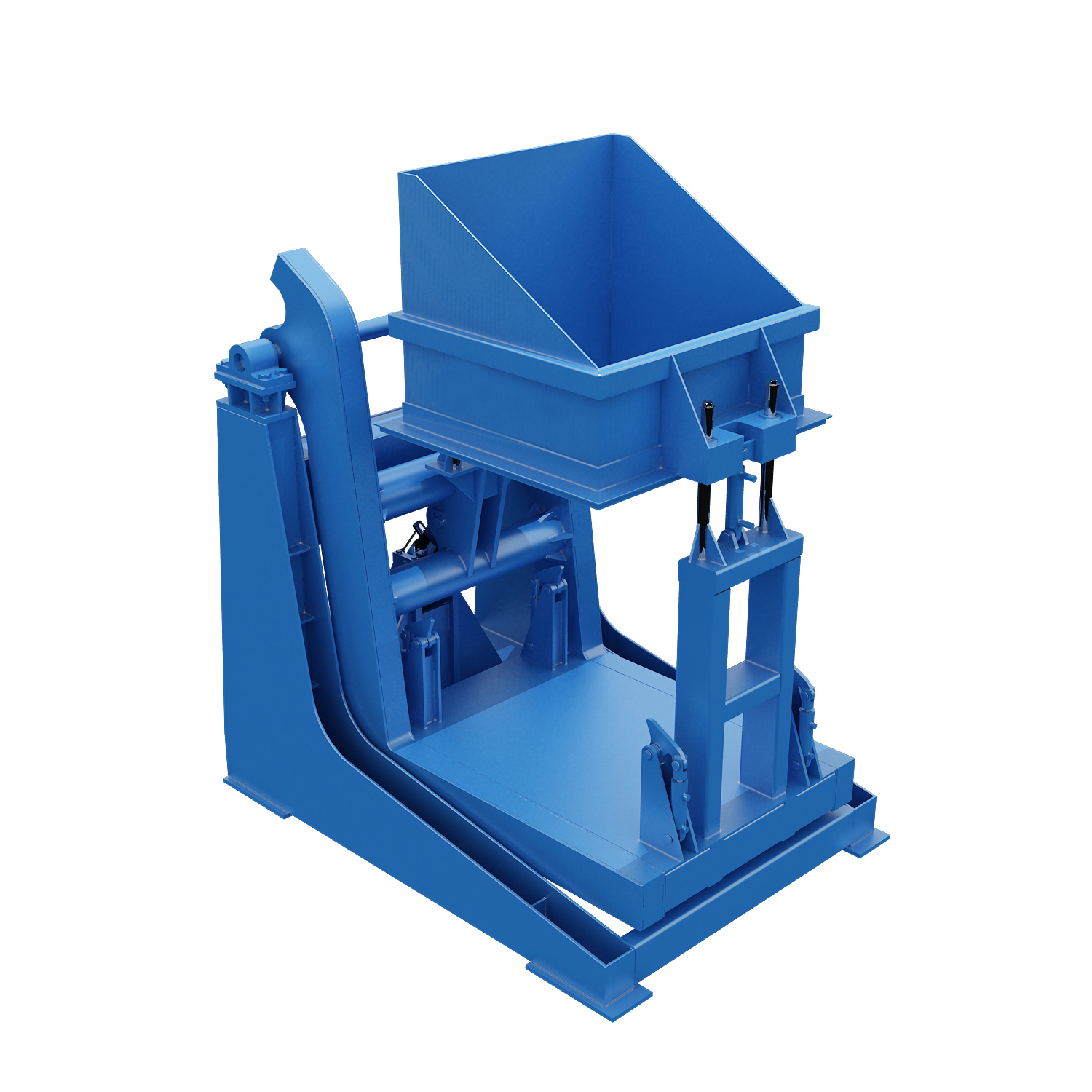

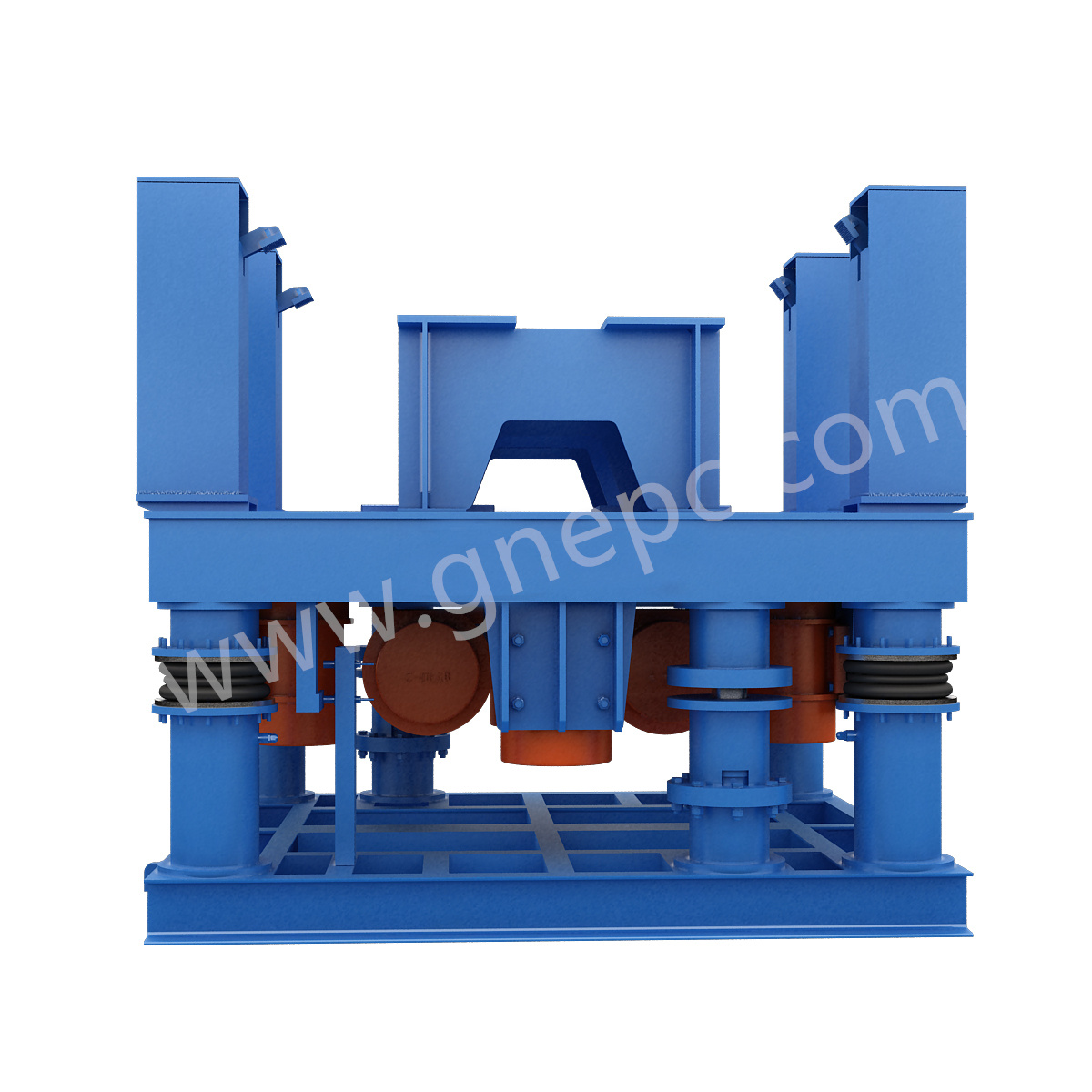

Casting separator

description2

product display

Equipment technical parameters

- ①Boundary dimension: 4000 × 1800× 1700 (height to be determined based on customer site);

- ②Sieve plate thickness: 20mm;

- ③Vibration motor: maximum excitation force: 40KN × 2; Power: 3KW × 2;

- ④Weight of screened castings: ≤ 200Kg.

Standard accessories

- ①Casting frame (including sand screen plate, inclined chute, and sand baffle);

- ②Motor support;

- ③Vibration motor × 2;

- ④Vibration spring × 8.

Main functions and advantages

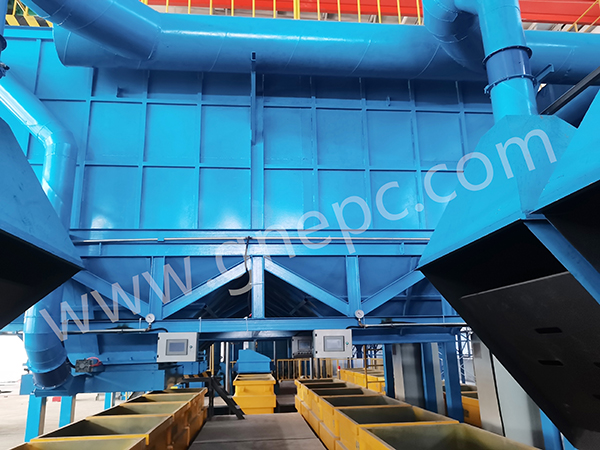

①Main functions: separation and transportation.

②Quickly separate the molding sand from the casting through a sieve plate, and send the casting out of the casting separator. The molding sand falls into the next level of sand treatment equipment through the hopper.

③Easy to operate, with options for fully automatic and manual control. Linkage action with the entire sand processing line during fully automatic control, without the need for worker operation; During manual control, the operator only needs to press the "Start" or "Stop" button.